Slotted Die

Product Features

General Specifications

Material

sts630, sts316l

Treatment

TiN, DLC

Adjustment Type

Flex-Bolt, T-Bar, T-Bar (Actuator - Auto)

Coating Spec.

Coating Speed

0.1 to 200 M/min

Coating Width

2,500 mm

Coating Thickness

1 to 1,000 um

Viscosity

1 to 50,000 cp.s

Machined Spec.

Straightness

5um ↓

Parallelism

5um ↓ , 10um ↓

Flatness

5um ↓ , 10um ↓

Roughness

Rmax 0.2 to 0.4

Product lineup

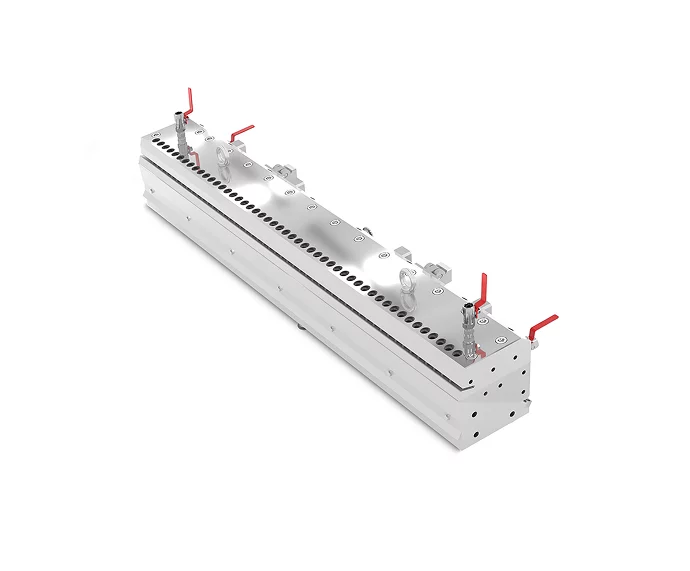

Single Layer Coating Die (Flex-bolt)

A typical slot die that coats a single layer at a time. flex bolts to control the coating thickness per section.

Dual Layer Coating Die (Flex-bolt)

A three-piece slot die that can coat two layers simultaneously, controlling the thickness of the coating from section to section on closely spaced flex bolts.

Single Layer Coating Die (T-Bar / Manual)

The same single-layer coating, but with a more precise T-bar adjustment via micrometer to control the coating thickness in sections.

Single Layer Coating Die (T-Bar / Automatic)

Connect a T-bar to a linear actuator to automatically adjust the thickness of the slot die section by section based on the coated result from the control system. Automatic Slot Die

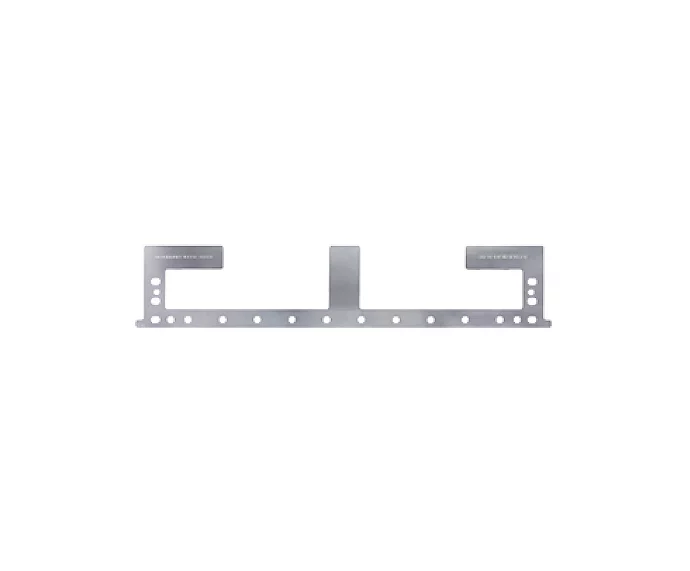

Normal Shim Plate

Precisely control coating width and thickness with precision-machined shim plates with specially ground edges to avoid sharp edges.

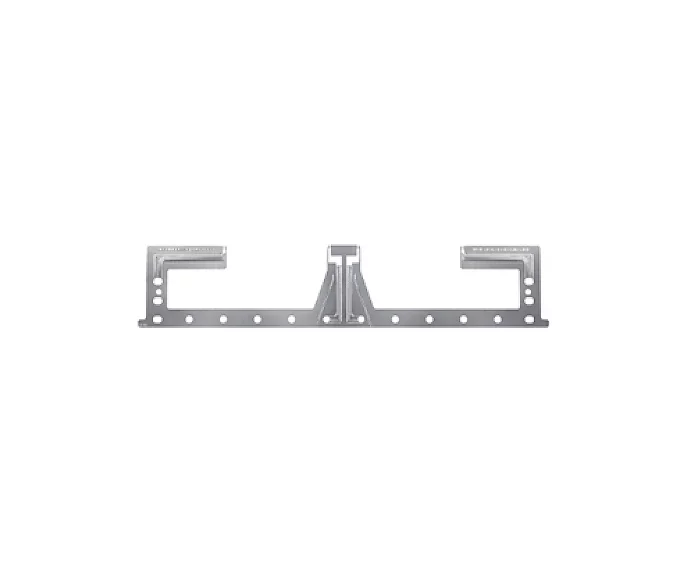

Etched Shim Plate

An additional precision-etched shim plate used primarily for insulating coatings.