Feeding system

Product lineup

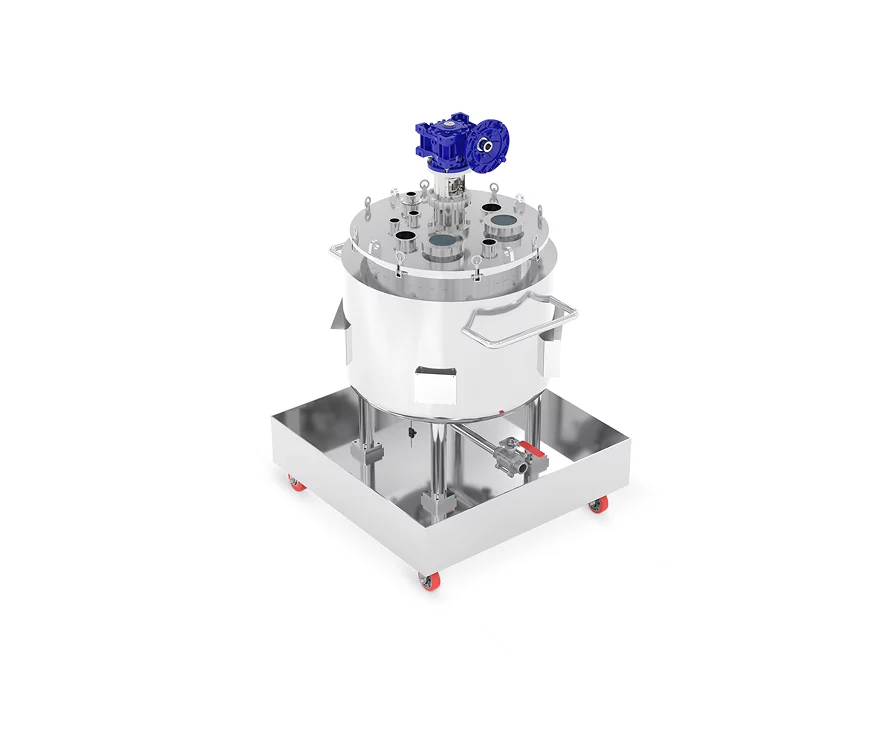

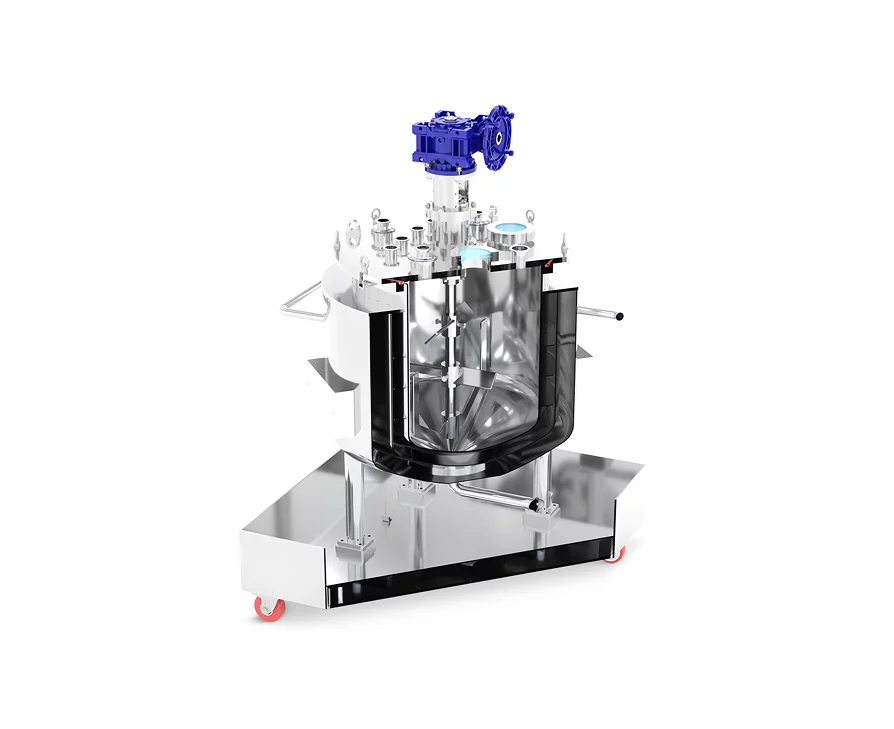

Mixing Tank

A tank that agitates solvents and powders into a slurry suitable for coating.

The basic material is stainless steel and consists of a stirring unit, a tank, and a mobile cart.

Options : Loadcell nit, Heating jacket

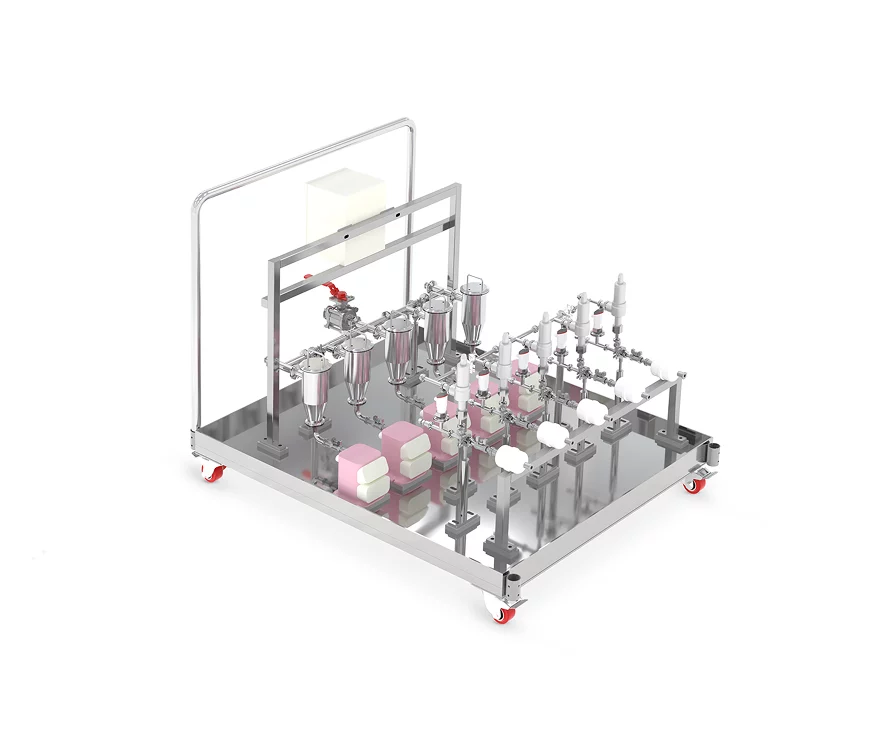

Feeding Unit

A unit that transfers the chemical solution (slurry) to be coated to the slot die, centered on a mono or diaphragm pump.

It consists of fluid control devices such as valves, flow meters, safety stools, and filters on a cart that can be transported by a piping system with attached filters.

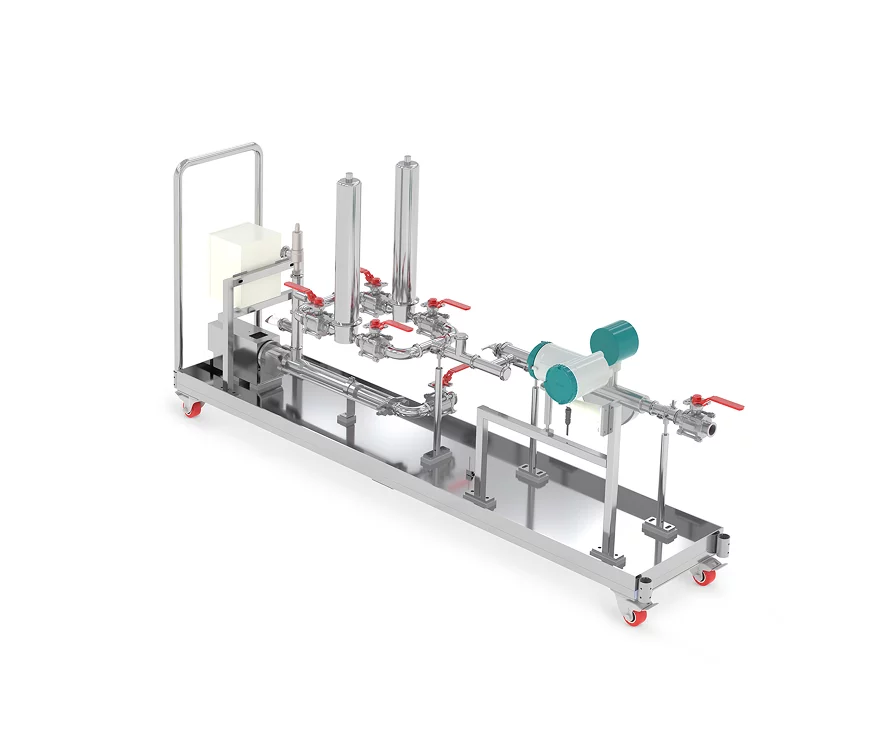

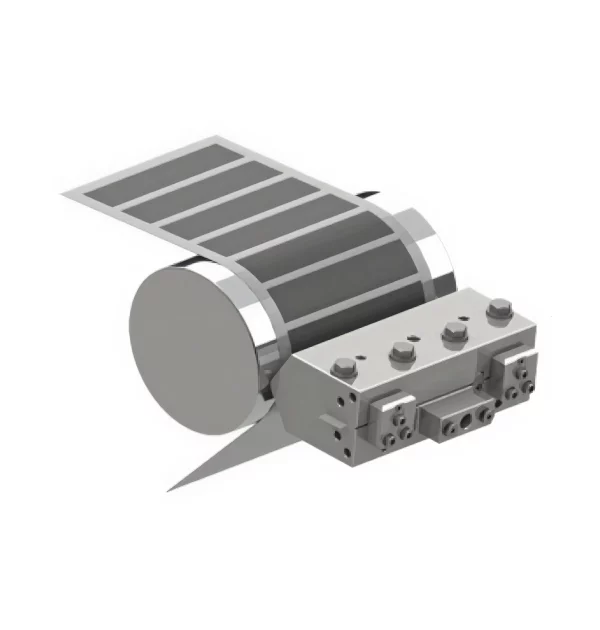

Pattern Valve

Intermittent coating by turning the coating on and off in the direction of travel of the substrate to be coated must be very precisely controlled by a specialized pattern valve unit.

In particular, we have successfully implemented high-speed intermittent coating in hydrogen fuel cell processes and offer specially designed pattern valves based on this know-how.

Pattern Valves

Pattern Coating Examples